Welcome to Pingyuan Huanyu Precision Machinery Co., LTD. Official website!

News

That's how you choose the handle! Very important, there are exquisite!

Release Time:

2018-12-28 09:54

According to different national standards

Divided into Japanese standard BT shank, German standard SK shank, HSK shank; International Standard IV or IT shank; American standard CAT handle.

According to the spindle taper hole

Divided into 7:24 taper universal shank and 1:10 HSK vacuum shank.

At present, according to the type of clamping

Divided into hydraulic tool handle, stress lock type tool handle, universal tool handle, thermal expansion tool handle.

The tool handle is an important bridge connecting the spindle and the tool

The value of the tool handle is insignificant compared with the value of the whole set, but it is an important bridge connecting the spindle and the tool, which has an important impact on the quality of processing. Modern large high-speed processing equipment is more and more applied to production, how to choose the right tool handle to adapt to the gradually increasing spindle speed of the machine tool, processing high precision mold surface, it is particularly important, technicians must consider the various characteristics of the tool handle, especially the clamping force and radial runout error accuracy and dynamic balance quality under the conditions of high speed operation. This helps to reduce the vibration of the tool itself.

Hydraulic tool handle

Hydraulic tool handle is a widely used tool handle. The clamping mode of the hilt is different from the traditional hilt system.

Tightening is done only with a pressure bolt, which, when tightened, pushes a hydraulic oil pressure generated by the piston seal block in the shank. This pressure is uniformly transmitted from the circumference to the steel expansion sleeve, and the expansion wall clamps the tool.

With the tool clamping system, the accuracy of radial runout error and repeated positioning can be controlled below 3μm. Because there is high pressure oil pressure in the tool handle, when the tool is clamped, the structure of the oil chamber and the existence of high pressure oil greatly increase the damping structure, which can effectively prevent the vibration of the tool and the spindle of the machine tool. On the actual application surface, using this fixture system can not only improve the machining precision and quality, but also make the service life of the tool in the cutting process be increased exponentially.

In addition to being maintenance-free and stain-resistant, the handle is easy to use and securely clamp the tool.

Stress locking shank

The stress lock shank adopts the multi-sided tool tightening mode, which is a very simple structure, but the design function is quite high clamping device. Tool clamping hole has a precise calculation and design of axisymmetric special polygon, with the help of a special loading device to apply pressure, forcing the clamping hole in the range of elastic deformation into a circular, so as to smoothly load the tool into the hole, after unloading the tool is a huge deformation recovery force firmly clamping.

Stress locking clamping system is widely used in lengthening rod, which can complete difficult machining tasks more flexibly. In particular, frequent tool replacement applications.

Universal shank

There are two main applications of universal shank: suitable for light machining applications and suitable for medium and heavy machining applications.

This type of shank uses an expansion technique similar to a hydraulic shank to clamp the tool, except that the expansion tension is obtained mechanically rather than through a hydraulic medium.

This advantage enables the user's tool handle system to achieve anti-vibration effect and high radial runout error accuracy.

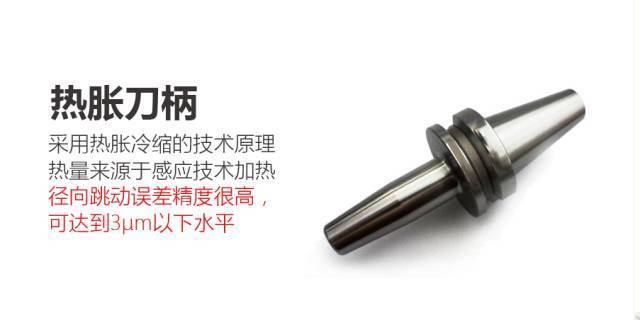

Heat expansion handle

Thermal expansion tool handle, the tool handle adopts the technical principle of thermal expansion and cold contraction, heat from induction technology heating.

The thermal expansion shank heating device has an induction coil that precisely heats the area of the tool inserted into the shank. After inserting the tool, the tool handle needs to be cooled for a period of time, which can be accelerated by the cooling sleeve. When the handle cools, it clamps tightly against the handle by its shrinking force. Through thermal expansion cold contraction clamping tool, clamping force is large, and can withstand high torque.

Through thermal expansion and cold contraction clamping tool almost becomes a very uniform force of the integrated tool, has a lot of advantages: radial runout error accuracy is very high, can reach the level of 3μm; The transmission torque is large, and the design of the shank is relatively small.

However, its disadvantage is that compared with hydraulic shank or stress lock shank, its vibration resistance is poor.

Common use of the handle

Very dainty

(1) Put the tool handle into the unloading seat and lock it tightly;

(2) According to the diameter of the tool select the appropriate spring, clean the working surface;

(3) Put the circlip into the locking nut;

(4) Load the milling cutter into the circlip hole, and control the suspension length according to the machining depth;

(5) Lock the lock nut with a wrench;

(6) Check, install the tool handle on the spindle;

Method of using hydraulic tool handle

Very dainty

Clean the protective oil on the hydraulic clamp before use.

Loosen the piston clamping screw and place the tool in the hole until contact is made.

Use a wrench to adjust the tool length by using radial or axial setting screws.

After the length is set, tighten the piston clamping screw to use.

What kind of handle system is best? There is no blanket answer to this question, as it depends on the specific application of the customer. A basic requirement for selecting the right shank is that you must understand the static and dynamic characteristics of the selected shank. These characteristics must be taken into account when customers examine their application needs and in order to determine safe and effective processing parameters.

It is very difficult to compare different shank systems because of their different machining principles, designs and methods, and their different advantages. These handles can only be compared at the same time under the requirements of a particular application. A more rigid shank is not suitable for all processing. A shank that is well suited for high speed machining may not meet some other machining needs.