Welcome to Pingyuan Huanyu Precision Machinery Co., LTD. Official website!

PRODUCT

Product accuracy is stable, appearance is clean and beautiful, complete specifications

Pingyuan Huanyu Precision Machinery Co., LTD

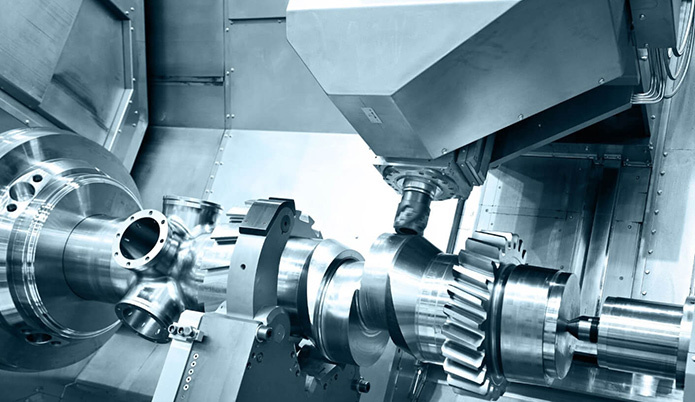

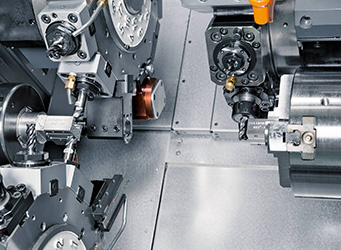

Huanyu precision machine was founded in 2005,is located in the plains of shandong Longmen economic and technological development zone,is a professional manufacturer of CNC milling system.The company's main products are:DIN69893(HSK),DIN69871(SK),DIN2080(NT),MAS 403(BT),CAT,ISO,the R8 the high-precision handle series of standard interface,high precision SDC,GSK,ER collet series and other products.Product accuracy stable,orderly and beautiful appearance,complete specifications.The company enjoys a self-supported import and export right,products sell well in the United States,Germany,Britain,Italy,Spain,southeast Asia and other countries and regions. Huanyu precision machine to produce "high precision,high speed" products as the guide,"professional,integrity,service" business philosophy,relying on strong technical force,advanced precessing and testing equipment,continuously providing high speed,high precision,high life products,meet the needs of customers and market.

More +

Why Choose Us?

Product accuracy is stable, the appearance is neat and beautiful

Professionalism and integrity

Advanced processing and testing equipment

High precision, high speed

Complete specifications

Meet customer and market needs

News Center

Products sell well in the United States, Germany, Britain, Italy, Spain, Southeast Asia and other countries and regions

08-23

2017

How to choose the handle correctly and control the cost effectively

A large number of factors, such as dimensional accuracy, surface quality, changing time and tool wear, will be affected by different clamping methods. Therefore, the tool handle has a direct impact on the quality of the workpiece and processing costs. In cutting, the handle is the key interface between the tool and the machine tool. In each processing occasion, whether the correct tool handle is selected will affect many factors, such as: dimensional accuracy, surface quality, changing time and tool wear, which ultimately affects the quality and cost of the workpiece processed.

08-23

2017

The difference between dynamic balance shank and ordinary shank

What is the difference between dynamic balance shank and ordinary shank? Why do we need dynamic balancing on the handle? Technicians from HAIMER, the manufacturer of the tool handle and dynamic balancing machine in Germany, have done experiments. By balancing the inserted tool and handle, the service life of the spindle can be doubled, the cutting amount can be increased by 10%, and the tool life can be extended by more than 10%.

08-31

2017

There are special requirements for HSK shank materials

Since the emergence of HSK hollow short taper shank technology, it has been widely used in the world. It is understood that some users in Europe and North America have experienced some problems with the HSK shank. The main reason for these problems lies in the poor choice of materials for making HSK shank.

10-26

2017

Use and instruction of HSK shank

High speed machining is not only the increase of spindle speed, but also the shortening of the overall processing time. Therefore, high-speed machining not only requires the cutting tool to have high rigidity, safety, flexibility, dynamic balance characteristics and convenience of operation, but also to the tool system and machine interface connection stiffness, precision and the clamping force and precision of the tool holder are put forward high requirements.